Japanese Knife Shop - SHARP KNIVES from Japan

For many centuries, the traditional craftsmanship of knife and sword making has lived on in Japan. It is not without reason that this tradition has been preserved to this day and continues to find new followers.

The most important characteristic is that a kitchen knife is sharp. That's why it was made. We import original Japanese knives that are hard to find elsewhere and bring the sharpest blades to Europe!

In this shop you will find hand-forged Japanese knives waiting to come to your home.

Discover traditional Japanese knives

Popular blog articles

Santoku vs. Gyuto

What is the difference between a Santoku knife and a Gyuto knife? Find out here in the blog.

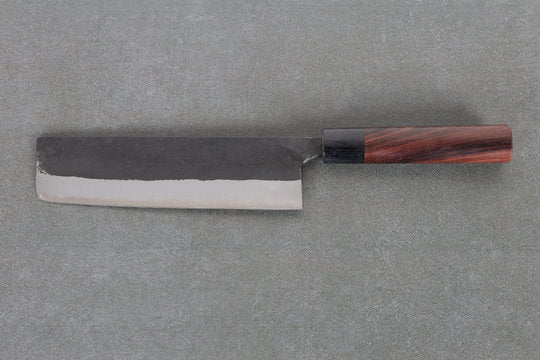

Japanese knives and their blade shapes

In this blog entry you will learn all about the different blade shapes of Japanese knives.

Durable sharp knife from Japan

Are you interested in

Japanese knives? Then you will be thrilled when you learn how

sharp knives can be. Japanese kitchen knives are designed to die

to deliver the sharpest cutting performance and "sharp" does not only mean sharp

but also reliable sharp performance over a long period of time.

We offer a wide range of traditional Japanese knives DIRECTLY from

Japan. Our high quality knives have been carefully tested and provide

best price-performance ratio. Together with our care instructions and

with Sharpening instructions you can easily care for your new Japanese chef's knife.

And keep it sharp!